Introduction

Today, refineries can evaluate their performance by comparing it with other refineries using two different indices: automation effectiveness and operational efficiency. Moreover, the indices are worth estimating financial investment, which might be necessary for upgrading the existing automated/nonautomated blending system to a contemporary blending control system.

This topic will discuss performance measurement methodology, blending performance, the automation effectiveness index, the operational efficiency index, the minimum and maximum automation effectiveness index, the relative rank of automation areas, tank farm automation status, etc.

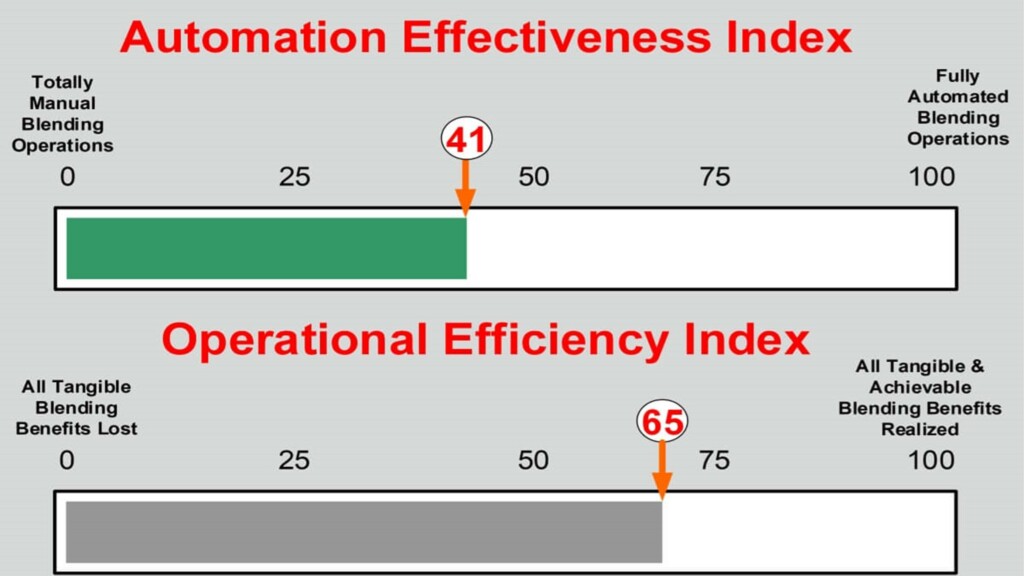

Automation Effectiveness Index

The automation effectiveness index helps to evaluate the extent of automation in the blending process. Therefore, the index might vary from refinery to refinery due to differences in the degree of automation. The automation effectiveness index is calculated by considering the data of software, hardware, blending control system, and equipment such as the pump station, tank farm for crude oil and finished products, control valves, sampling methods, and analyzers.

Minimum Automation Effectiveness Index

Automation effectiveness is at a minimum when the index value is zero, and all the processes are conducted manually, such as manual tank gauging. There are no distributed control systems, programmable logic controllers, or advanced process control. Moreover, linear blend models are utilized in the blending process.

Maximum Automation Effectiveness Index

Automation effectiveness is at a maximum when the index value is 100. Here, nonlinear blend models and in-line blending are used to achieve precise results. In addition, all the processes are automated here, such as automatic tank gauges and distributed control systems.

Operational Efficiency Index

This index takes into account operational determinants such as time, cost, and quality. Therefore, it helps to evaluate whether the blending operations are carried out as per the requirements. It also evaluates the probability of profit improvement per year.

Relative Fuel Blending Benchmarking Indices

The operational and automation effectiveness indices can be generated for any refinery and compared with other refineries. As a result, the scope of improvement in automation can be easily identified using this methodology.

Summary

Many refineries are adopting automated methodologies to increase their productivity and profit. As a result, operational efficiency and automation effectiveness indices can be calculated based on the refinery’s configuration.

Options for eLearning This Topic

Browse Our Academy Course Catalog

#OperationalEfficiencyIndex #AutomationEffectivenessIndex #BlendingControlSystem #ManualTankGauging #LinearBlendModels #ProgrammableLogicControllers #NonlinearBlendModels #In-LineBlending #RelativeFuelBlending #Refinery’SConfigurationModel

![[V25N1] - ROI of Implementing Oil Movement & Blending 2 1744916426062](https://cdn.oms-elearning-academy.com/wp-content/uploads/2025/04/1744916426062-300x169.jpg)

![[V24N1] - Refinery Management: Ignorance or Indifference of Hidden Gold? 16 996299000006236004 zc v1 1747302739540 pros and cons of remote workforce oms experience](https://cdn.oms-elearning-academy.com/wp-content/uploads/2025/06/996299000006236004_zc_v1_1747302739540_pros_and_cons_of_remote_workforce_oms_experience-300x169.jpg)