Introduction

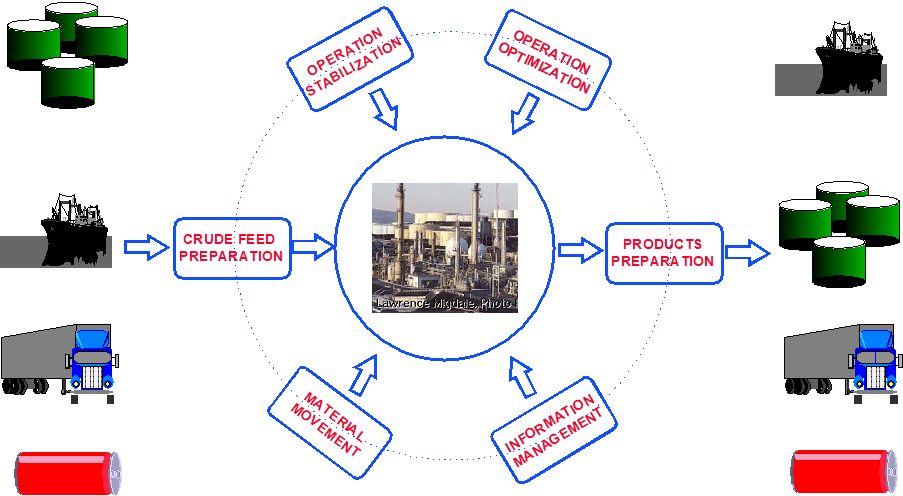

The activities of a typical refinery or any processing plant can be categorized into a number of major broad areas. The viability of a plant depends upon how these areas are managed, integrated, and structured to meet operational requirements, market demand, fluctuating source and quality of raw materials, and many other factors which are sometimes unpredictable and may be uncontrollable.

This paper discusses the automation modules required for integrated Advanced Control and Optimization Systems for a Refinery.

Table -1 below gives the refinery activity and related integrated computer control and/or optimization system for the activity.

|

Refinery Activity

|

Integrated System

|

This blog discusses the scope and benefits of the following three integrated computer control and optimization systems for the activities given in the above table.

- Crude Blending Control and Optimization

- Product Blending Control and Optimization

- Oil Movement & Storage system

Since the details of each of the above systems are discussed separately elsewhere, this blog presents only an overview of these systems to indicate their complexity and importance for an automated refinery.

Figure 1. Major Activities in a Typical Refinery

#IntegratedRdbmsModule #IntegratedRdbmsModule #ProductsBlendingControl #CrudeQualityControlIntegration #On-LineBlendControl #RegulatoryBlendControl #PhysicalRefineryConstraints #ConfigurationsBlendingSchemes #RefineryCrudeBlending #OilMovementStorage #RefineryFeedStocks #OperationalDataAnalysis #Off-LineBlendControl

![[V25N1] - ROI of Implementing Oil Movement & Blending 2 1744916426062](https://cdn.oms-elearning-academy.com/wp-content/uploads/2025/04/1744916426062-300x169.jpg)

![[V24N1] - Refinery Management: Ignorance or Indifference of Hidden Gold? 16 996299000006236004 zc v1 1747302739540 pros and cons of remote workforce oms experience](https://cdn.oms-elearning-academy.com/wp-content/uploads/2025/06/996299000006236004_zc_v1_1747302739540_pros_and_cons_of_remote_workforce_oms_experience-300x169.jpg)

Crude blending

A typical refinery gets its crude supply from various sources that vary greatly in properties such as density, sulfur content, and volatility, and consequently, vary the feed quality to the crude unit. Ideally, the crude distillation unit in the refinery needs to be optimized online for yield and cut quality for product blending and other product slates for every crude feed, but may cause variation in the tower operational parameters and may not be desirable. Alternatively, crudes from various sources may be blended upstream to produce a uniform feed to the crude unit. The implementation of crude blending control and its integration with other sub-systems can achieve the following objectives.

The integrated crude blending system

The benefits of crude blending by itself can not be realized unless it is integrated with other sub-systems for optimization, operational stability, and just-in-time manufacturing. These sub-systems can be categorized into two areas, namely, modules for crude quality control integration and modules for product quality control integration.

Crude quality control sub-systems

The crude quality control sub-systems and their roles in integration are as follows:

Product quality control sub-systems

Figure-2 shows a graphical representation of crude quality control and product quality control sub-systems for an integrated crude blending, scheduling, and optimizing system.

Figure 2. Integrated Crude Blending Control System

Feasibility of crude blending in a refinery

Operational data analysis

Operational and physical constraints

Figure 3. Configuration of tank-to-units Transfer Activities

Configurations of blending schemes

It is clear from the previous section that the configuration of the blending scheme for crude depends greatly on the operational and physical constraints and may defeat the economic advantages. There are three following scenarios for the blending of crude.

Figure -4 shows various schemes for unloading and blending of crude from ships to tanks. Transfer types I and III unload crudes into tanks directly and later may be blended from tank to tank to prepare the final crude feed. However, integration of scheduling and tank inventory, and composition modules, as discussed earlier in this blog, will be necessary to implement any blending schemes. Such integration of application modules would alleviate some of the physical and operational constraints.

Figure 4. Configuration of “Ship to Tank” Transfer Activities

At any given time both physical and operational constraints govern the feasibility of one blending scheme over another. For example, physical constraints such as the availability of crude tanks will determine the feasibility of crude unloading and its blending into tanks at the same time or later for tank-to-tank blending configuration. On the other hand, operational constraints will determine the need for inline blending to crude units.

It is important to realize that although the integration of all modules discussed earlier in this paper would stabilize the quality of feed to distillation unit to achieve the product quality targets and improve the operational stability of the distillation unit, there may be a situation where an individual module is implemented for one reason or other. For example, if physical constraints do not permit for “ship to tank” or “tank to tank” blending of crude oil, inline crude blending to a crude unit can accomplish the same objective to a certain extent.

It is worth noting here that tank-to-tank blending has more degrees of freedom (depending upon the number of available crude storage tanks) than inline blending to crude units. In an inline blending scheme, crudes are blended usually for density control purposes only since the API density determines the crude distillation curve.

Products blending

The blending of products such as gasoline, diesel, and fuel oils has become increasingly complex process and demanding because of competition and new EPA regulations for the newly formulated types of gasoline. Refineries suffer big economic losses due to quality giveaways of Octane and RVP, time lost in reblending, not meeting markets demands because of inadequate product inventory due to shortage of tanks, etc. The refining industry around the world is placing emphasis on automation of their refining and blending operations using the latest technology to meet the market demands of tomorrow and stay in today’s cutthroat business.

This blog discusses the essential elements of an integrated blend control system for the planning, control, and optimization of their blending operations. This blog also presents the system architecture of an integrated blend control system using state-of-the-art equation solvers and optimization tools, blend models, software, and hardware sets. The blog also discusses the tangible and intangible economic benefits of an integrated blend control system.

Automation levels of blending control

In earlier years, before the advent of computers and digital instrumentation, refiners and others plants used to perform blending totally in a manual manner or “bucket mixing” approach according to predetermined proportions of ingredients. Severe competition, a decline in profits, and scarcity of raw materials forced refiners to consider other methods to stay in business. Three levels of blending control strategy have evolved over the last 15 years in the refining business and they are discussed briefly in the following paragraphs.

Regulatory blend control (RBC)

The first level of blend control strategy resides in a DCS such as ABB MOD-300, Honeywell TDC-3000, Fisher ProVox, etc., and controls the amount of each component in the final product tank automatically by computer. Although this level of computer does not give any guarantees to blend the product to specifications as it does not use any analyzer feedback, it does relieve the operator from monitoring the process continuously.

Advanced blend control (ABC)

The second level of the blend control strategy is a scheme that is implemented in another computer such as VAX, HP Workstation, IBM, etc., and is linked to DCS executing the first level of control. This control uses the analyzers feedback, corrects the recipe frequently, and guarantees the final product on specifications. This is a very complex technology and saves the refinery lots of money because of continuous optimization and feedback.

Off-line optimization and planning system (OOPS)

The third level of the blend control strategy is offline optimization of a blend recipe taking into account the refining process as expected in advance. This is done on a Personal Computer (PC) by a refinery planner and then he downloads the optimized recipe to the online blend control (ABC) system for further online control and optimization and is finally executed in DCS by RBC. The planner typically may plan many recipes at one time depending upon refinery operational characteristics.

Figure 5. shows all levels of blend control, optimization, and planning system modules in an integrated environment

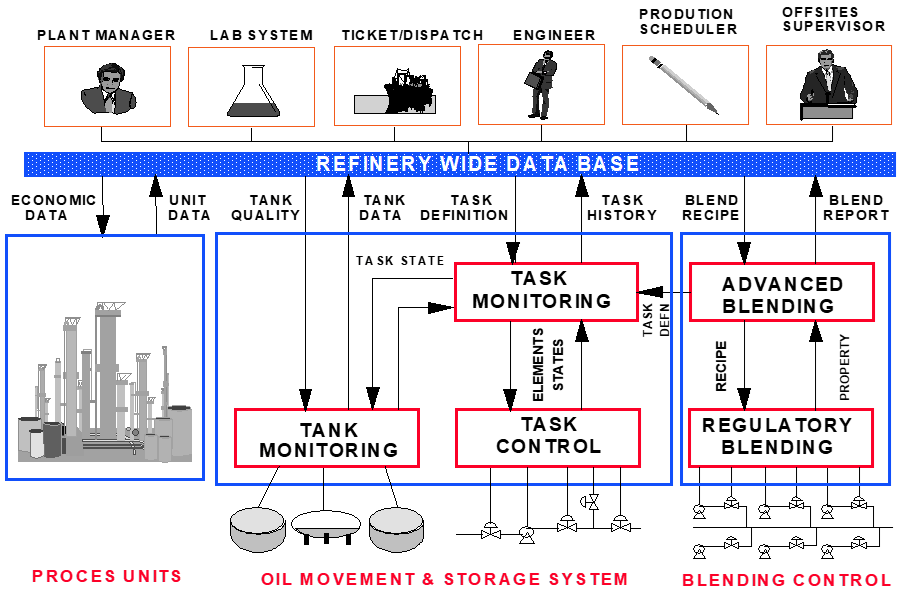

The integrated products blending system

Integrated blend control, optimization, and planning systems are implemented separately for the blending of middle-distillate and motor gasoline products in a refinery. Such an integrated system usually consists of the following minimum numbers of modules and is integrated through a Relation Database Manager System (RDBMS) such as Oracle, Interbase, Informix, Sybase, etc.

Figure -6 gives a typical architecture of an integrated blend control, optimization, and planning system. The modules in Figure -3 represent the minimum requirement for an integrated system. Although there are some other modules desirable in a more flexible and robust system, they will not be discussed in this blog.

Figure 6. The architecture of an Integrated Blend Control, Optimization, and Planning System

Oil movement & storage

The functional capabilities of an Oil Movement and Storage (OM&S) system is primarily concerned with the transfers of bulk liquids within and across the refinery’s boundaries. Unlike the long-term, continuous, steady-state, and complex operating characteristics of the processing units, these bulk movements tend to be batch operations of comparatively short duration, imposing relatively simple control requirements. However, what makes the transfer activities tedious, performed manually, in a refinery is not the nature of their control functionality but factors like their numerous types, the large number of repetitions subject to inefficiencies, operating problems, and economic loss, etc.

This blog gives an overview of the typical refinery oil movement activities, problems connected with them, and concepts of automation of an Oil Movement and Storage (OM&S) system.

Refinery OM&S activities and their interactions

Typically, an oil movement and storage operation in a refinery involves efficient management of

This equipment and tanks may be involved in one or more of the following activities:

There may be as many as 80-90 different types of jobs or tasks involving these activities per day and these activities not only require the constant attention of the OM&S operator for the management of these tasks but they are highly interactive in nature, making them subjected to possible product contamination and accidents.

Problem areas of OM&S activities

It is quite natural that the management of such a large and complex network of equipment and transfer activities in a refinery and has some problems associated with it. Problems typically associated with OM&S activities can be classified into the following four areas:

The following sections will discuss each of the above problem areas in detail.

Decrease in plant profitability

The plant profitability may be decreased due to the following factors:

Figure 7. Interaction of OM&S Activities

Operating problems

Operating problems vary from the areas related to man/machine interfaces to errors by the filed operators and may result in economic losses. Some of the most common operating problems are:

Product losses

The direct effect of product losses is the decrease in the plant profitability and the followings factors contribute to this problem area:

Operating costs

In addition to economic loss to the plant by problems areas discussed in earlier sections, a plant may also incur an increase in operating cost due to the following factors:

Most of the problems in the areas discussed in the above sections can be either eliminated or reduced by implementing computer automation of oil movement and storage. The next sections will discuss some of the concepts and features of the automation of OM&S available today in the market.

Computer automation of OM&S

The automation of oil movement and storage operation requires that the computer system responds to the needs of the operator to perform the major functions discussed below.

Functionality

The above characteristics of a well-designed and developed OM&S computer system provide interfaces and interaction among all activities of OM&S operations in a refinery. Figure -8 shows the flow of information among OM&S activities and OM&S computer system,

Levels of OM&S control functions

The functionality of automated OM&S system can be translated into various control levels, as shown in Figure -9., are discussed below:

Figure 8. Computer Automated OM&S System

System integration

The components of an integrated OM&S computer system would depend upon the status of automation and refinery information systems in a particular refinery and the computing platforms of the OM&S system. For example, commercially available OM&S systems either from IBM or Honeywell include blending as one of the modules. OM&S algorithm as such does not include any linear programming (LP) algorithm whereas the inline blending uses either LP and non-linear equation solver and optimization using non-linear blend models depending upon the type of product blend. In addition to this, a truly integrated OM&S system must interface with the refinery’s information management system for history, databases, reports, reconciliation, etc. This results in customized integration of the OM&S system for each refinery and may involve developing many interfaces for various modules and computers.

Figure -10 shows a typical automation architecture of an OM&S system.

Figure 9. Control Levels of Automated OM&S System

Figure 10. The architecture of a Typical Integrated OM&S System

Benefits

An integrated blend control and optimization system offers great economic benefits for a typical refinery and various modules discussed in this paper offer both tangible and intangible benefits. Table-2 shown below summarizes a typical range of average benefits for a 100,000 Bls/day refinery. The typical payback period for the implementation of an integrated blending system is usually 1-2 years.

Table 2 Tangible Benefits of Integrated Advanced Control Systems

Total=$10-14M/Year

Summary

This blog has discussed the concepts of three major integrated control systems which can save a refinery between 10-14 M$/Year in benefits. However, these systems can be implemented in phases to realize each one of them individually. Since oil movement and storage system is used for both blending systems, it must be implemented first keeping in mind the overall integration of all three and other computer systems in the plant.

References